As I mentioned at the end of last week, I’m going to go through some of the DS FAQ this week. Rather than just dump it into the file, I’m going to post these additions up as discussion articles for a few days first. This is partly because I like discussing stuff with you guys, but mostly because I’ve not played a lot of DS from the printed rules, and it’s the printed rules we need to check rather than what I remember or might have written in one of the many pre-production versions.

As I mentioned at the end of last week, I’m going to go through some of the DS FAQ this week. Rather than just dump it into the file, I’m going to post these additions up as discussion articles for a few days first. This is partly because I like discussing stuff with you guys, but mostly because I’ve not played a lot of DS from the printed rules, and it’s the printed rules we need to check rather than what I remember or might have written in one of the many pre-production versions.

FYI, I’m using the Adventurer’s Companion version of the rules as reference because that’s what I can find.

So, without further ado, Line of Sight (LOS).

The intent with DS was to make it fairly liberal, and also to avoid needing to decide where the centre of the squares were. The LOS rule could be rephrased as follows:

To find out if there is a clear LOS to your target, answer this question:

Can you can trace an unblocked straight line from any part of the shooter’s square to any part of the target square?

If yes, then you can shoot. If no, then you cannot.

Note that if you can trace any unblocked line then you answer yes to this question. It doesn’t matter if some lines are blocked and others not, as long as some are not.

I think this is simple enough so far.

What constitutes blocked then? Going through the middle of a square with a model, wall, or piece of furniture in seems obvious. The question really seems to be whether a blocked square blocks its edges and corners as well as its centre, or whether you can skirt around this. Actually, the photo on page 22 shows this must be blocked because Madriga cannot see the Zombie behind the bookcase. This gives us the ruling that:

A square containing a model, wall or other obstacle completely blocks any LOS that touches that square, including those that go exactly along an edge or touch a corner.

Again, that seems reasonably simple to implement.

The note on page 28 explains that some furniture is short enough to shoot over. The modifier for this only applies if there was no LOS that avoided crossing the obstacle. Always assume that the clearest LOS is the one the shooter is using.

While I think this resolves the queries I’ve seen, there is one related question that does not, strictly, involve LOS (because it’s not about shooting). Can I fight an enemy that is diagonally adjacent to me when both orthogonally adjacent squares to either side of him are blocked? The answer here is yes, you can. A fight is a fast and fluid thing, not like our static models at all. You’re also right up close (whereas shooting is always further back). For this reason I think it reasonable that a combatant can sneak a quick stab in against an opponent that is adjacent to him, regardless of the artificial grid we have imposed for ease of movement. Speaking of movement, this would be blocked, like shooting. Easier to sneak a blade through a gap than a whole Dwarf 🙂

If any of the squares a model covers are in the area marked in front then it counts as being in front of the target.

If any of the squares a model covers are in the area marked in front then it counts as being in front of the target. I’ve been going to this show for years now, and every year it’s grown. This year is the first in the NEC, one of Britain’s largest exhibition centres, having outgrown the large hotel/conference centre it took over last year. The need was obvious – last time there was gaming in every nook and cranny of the hotel, not to mention the competitions in marquees in the grounds and the gaming in the halls and visitor’s rooms themselves. Even the food had been evicted to make way for more gaming, meaning that the car park was full of all varieties of food vans, a beer bus (below), and other routes to culinary satisfaction. Way better than the usual solitary burger van or greasy spoon you get at gaming shows though – an excellent solution.

I’ve been going to this show for years now, and every year it’s grown. This year is the first in the NEC, one of Britain’s largest exhibition centres, having outgrown the large hotel/conference centre it took over last year. The need was obvious – last time there was gaming in every nook and cranny of the hotel, not to mention the competitions in marquees in the grounds and the gaming in the halls and visitor’s rooms themselves. Even the food had been evicted to make way for more gaming, meaning that the car park was full of all varieties of food vans, a beer bus (below), and other routes to culinary satisfaction. Way better than the usual solitary burger van or greasy spoon you get at gaming shows though – an excellent solution.

If you’ve not been before and are at all interested in games, I’d recommend you try to pop along at some point this weekend. You can get a ticket on the day, it’s very family friendly, and it has a very high female/child count (for a game show) – almost as if gamers were part of the real world!

If you’ve not been before and are at all interested in games, I’d recommend you try to pop along at some point this weekend. You can get a ticket on the day, it’s very family friendly, and it has a very high female/child count (for a game show) – almost as if gamers were part of the real world! This year I’m wandering about like the penguins, above. I’ve been on trade stands before, and next year I have possibly 3 different stands I might have to flit between, but this year I’m just drifting about, seeking things to amaze and amuse myself. That means that I get to play some of the many games on offer, and I expect there to be a great many to choose from. Ice Cool (above) is one I’m looking forward to trying my hand at, but there will be loads more – way more than I can fit in during a mere 3 days. Calling the main space the Trade Hall makes it sounds like a big shop, and there will doubtless be plenty to buy. However, there’s always a bewildering array of games to play as well, and hundreds of people who would just love to run you through a demonstration of their latest masterpiece. Some of these will be buyable on the day, but increasingly there are people previewing early copies of things that are set of Kickstarter or Indiegogo. A sign of the times.

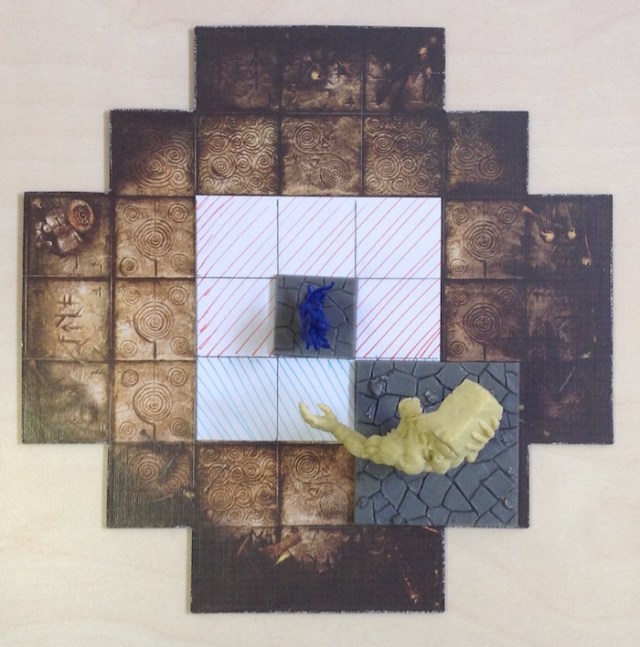

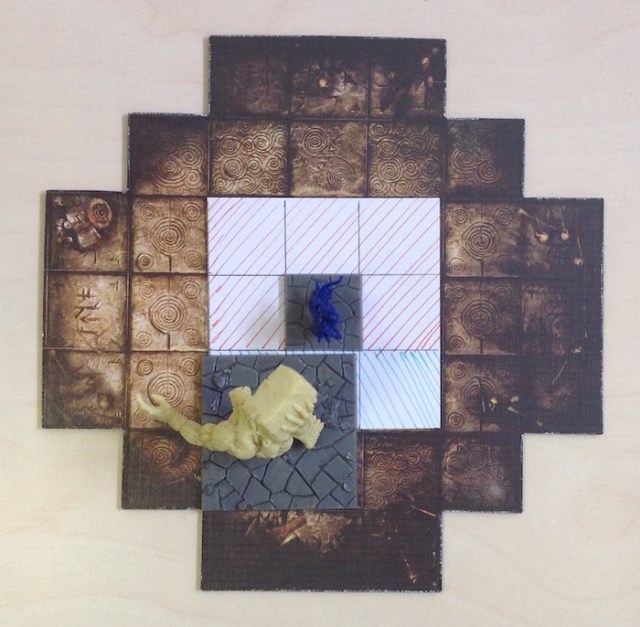

This year I’m wandering about like the penguins, above. I’ve been on trade stands before, and next year I have possibly 3 different stands I might have to flit between, but this year I’m just drifting about, seeking things to amaze and amuse myself. That means that I get to play some of the many games on offer, and I expect there to be a great many to choose from. Ice Cool (above) is one I’m looking forward to trying my hand at, but there will be loads more – way more than I can fit in during a mere 3 days. Calling the main space the Trade Hall makes it sounds like a big shop, and there will doubtless be plenty to buy. However, there’s always a bewildering array of games to play as well, and hundreds of people who would just love to run you through a demonstration of their latest masterpiece. Some of these will be buyable on the day, but increasingly there are people previewing early copies of things that are set of Kickstarter or Indiegogo. A sign of the times. The Troll counts as being in the Hero’s front arc here:

The Troll counts as being in the Hero’s front arc here: And here:

And here: And in the rear arc here:

And in the rear arc here:

So, if any of the squares occupied by the base of the Large or Huge model are in the front arc of the target, then it is in the target’s front arc.

So, if any of the squares occupied by the base of the Large or Huge model are in the front arc of the target, then it is in the target’s front arc. As I mentioned at the end of last week, I’m going to go through some of the DS FAQ this week. Rather than just dump it into the file, I’m going to post these additions up as discussion articles for a few days first. This is partly because I like discussing stuff with you guys, but mostly because I’ve not played a lot of DS from the printed rules, and it’s the printed rules we need to check rather than what I remember or might have written in one of the many pre-production versions.

As I mentioned at the end of last week, I’m going to go through some of the DS FAQ this week. Rather than just dump it into the file, I’m going to post these additions up as discussion articles for a few days first. This is partly because I like discussing stuff with you guys, but mostly because I’ve not played a lot of DS from the printed rules, and it’s the printed rules we need to check rather than what I remember or might have written in one of the many pre-production versions.